Description

Upgraded Brake Kits

- X-Line billet 6-piston off-road calipers.

- Larger diameter rotor maximized for the truck application

- Rotor has internal curved, directional cooling vanes.

- Billet caliper mounting brackets.

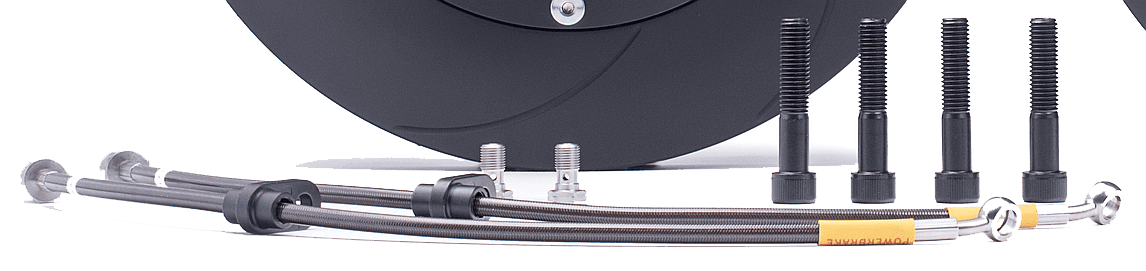

- Stainless steel braided brake lines.

- All necessary mounting hardware for quick, easy bolt-on installation.

- Comprehensive install and bed-in instructions.

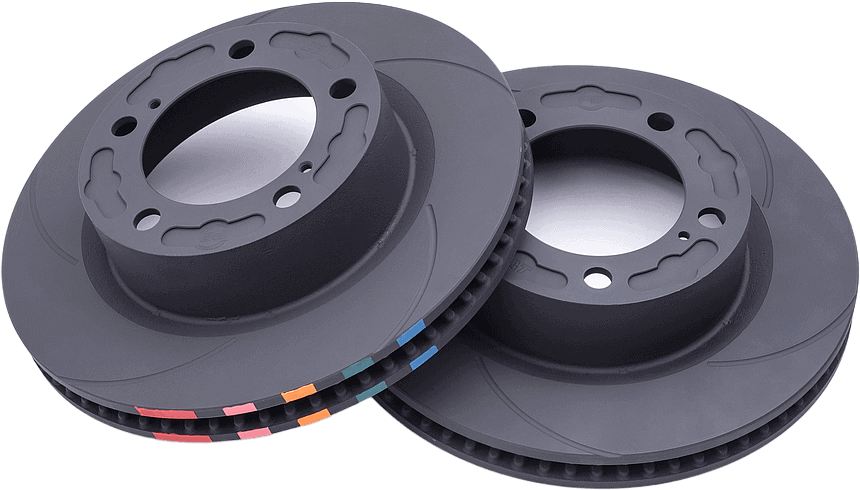

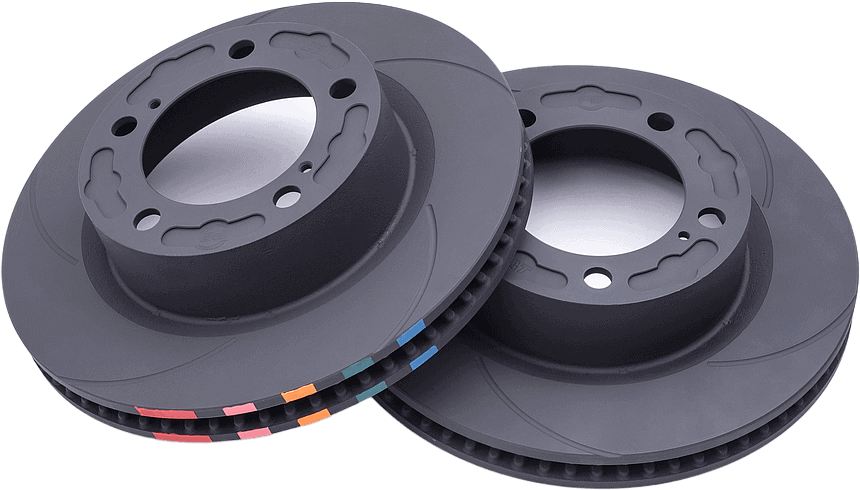

Rotors

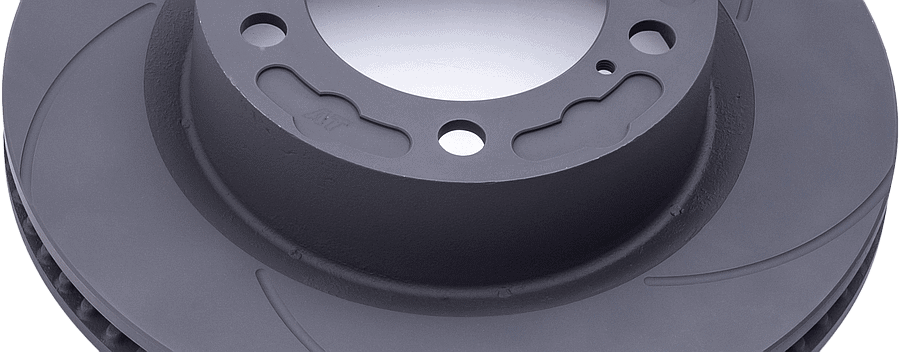

The rotors utilized in our X-Line 4×4 big brake kits are crafted from a proprietary high-carbon cast iron alloy, ensuring exceptional durability and stability even during high thermal loads experienced in both street and off-road driving. Notably, these rotors feature curved, directional cooling vanes, significantly enhancing cooling efficiency by maximizing surface area and airflow compared to factory or OEM rotor designs.

For our X-Line 4WD rotors, we employ the proven “AT” slot pattern, striking a fine balance between functional aspects such as efficient removal of sand, mud, and water (especially when driving in rainy conditions or after river crossings) and practical aspects such as minimizing noise, vibration, and harshness (NVH) during braking. This slot pattern also delivers excellent bite and release characteristics.

Every single Powerbrake rotor undergoes precise measurement for run-out and disc thickness variation (DTV) using Swiss measuring equipment. We prioritize quality control without relying on batch or statistical checks – each rotor undergoes individual measurement. Our machining tolerances surpass the industry norm by up to threefold.

Rotor Surface Coating

All our X-Line 4WD rotors feature a proprietary black surface coating. Before applying this coating, the rotors undergo chemical de-greasing to ensure the absence of machining fluids or contaminants that could negatively impact brake performance. The coating exhibits exceptional heat resistance and flexibility, preventing flaking or peeling during the rotor’s thermal expansion and contraction cycles.

Our X-Line 4WD rotors require no solvent-based cleaning or preparation. Simply make sure the car’s hub is clean and install the rotors as they come out of the box. The brake pads will remove the black coating in the pad track areas within the first 4-5 brake applications, while the un-swept areas of the rotor will retain the coating. Although the primary purpose of our rotor coating is to eliminate oils and contaminants during fitting (rather than providing corrosion protection), practical experience has shown that the non-swept areas of our coated X-Line 4WD rotors effectively resist unsightly surface rust formation, depending on environmental conditions. This results in a visually appealing appearance visible through the truck’s wheels.

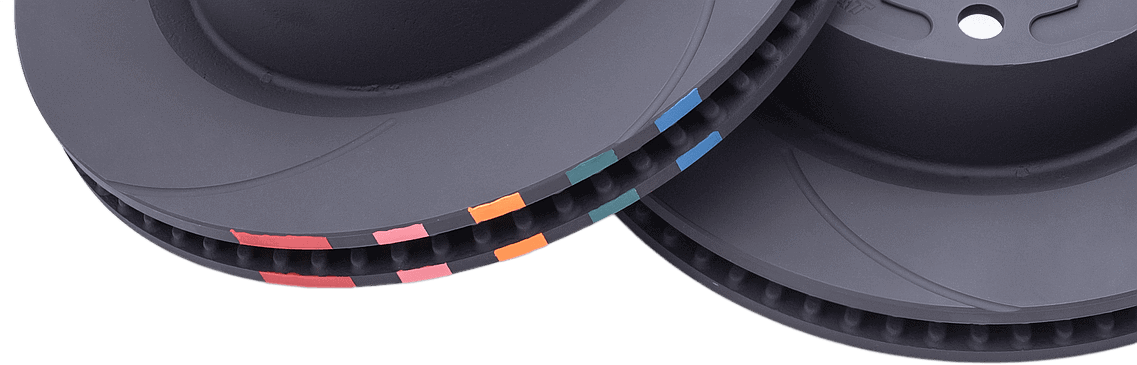

Rotor Maximum Temperature Recording (MTR) System

All our rotors feature our MTR system that provides a permanent record of the peak operating temperature reached by the rotor. This information is extremely valuable for understanding what is happening in your brake system. The thermal-paint tabs are applied to the outside diameter of the rotors (on both the inboard and outboard rotor plates). Each single-change paint color will change to white when a specific temperature is reached, hereby providing a record of the peak operating temperature of the rotor.

- Blue paint changes color at 527 deg F

- Green paint changes color at 860 deg F

- Orange paint changes color at 1022 deg F

- Pink paint changes color at 1166 deg F

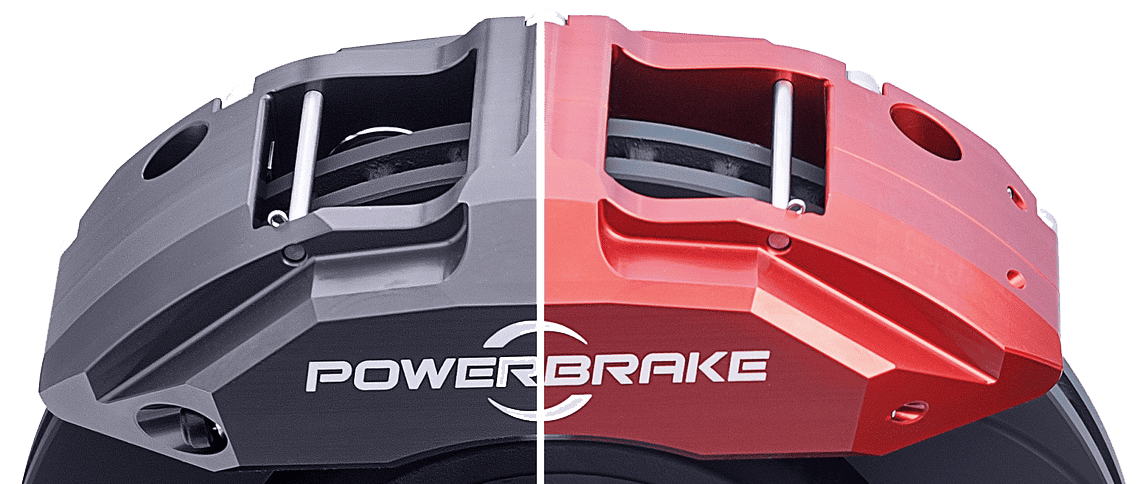

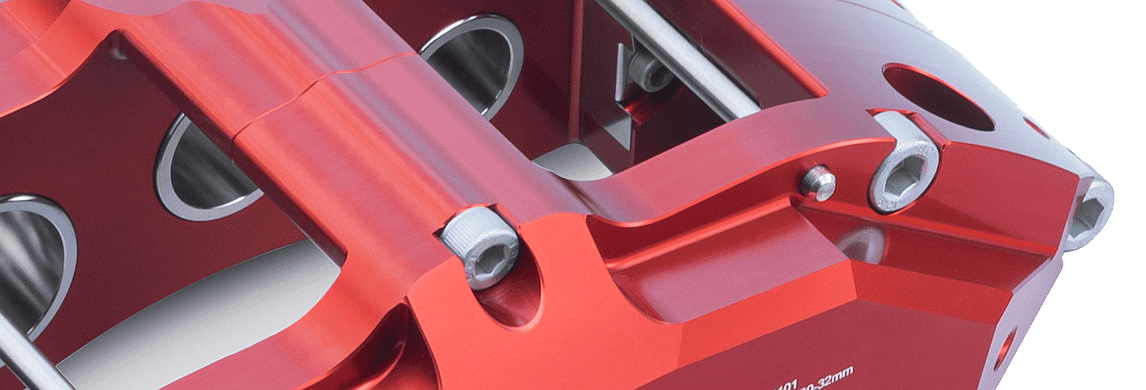

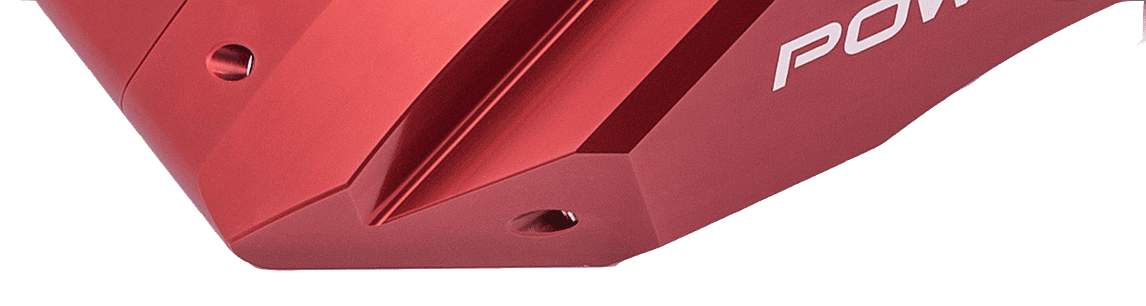

Caliper Construction

At Powerbrake, we firmly believe in the advantages of machining our multi-piston calipers from solid billet. All our calipers are precision-machined using high-grade aerospace aluminum billets. Although machining from billet is an expensive manufacturing method, it yields a final product with exceptional strength and rigidity.

How do we offer our billet X-Line 4WD calipers at competitive prices? We achieve this through substantial investments in cutting-edge 5-axis CNC production equipment, ensuring maximum efficiency in caliper machining. The combination of machining from billet and the caliper designs enhanced through Finite Element Analysis (FEA) results in calipers with an impressive rigidity-to-size ratio. The slender profile of the calipers reduces unsprung weight and enhances wheel clearance

Caliper Surface Finish

Caliper Logos

Caliper Cross-Bolts

Caliper Pistons

Internal Fluid Crossovers

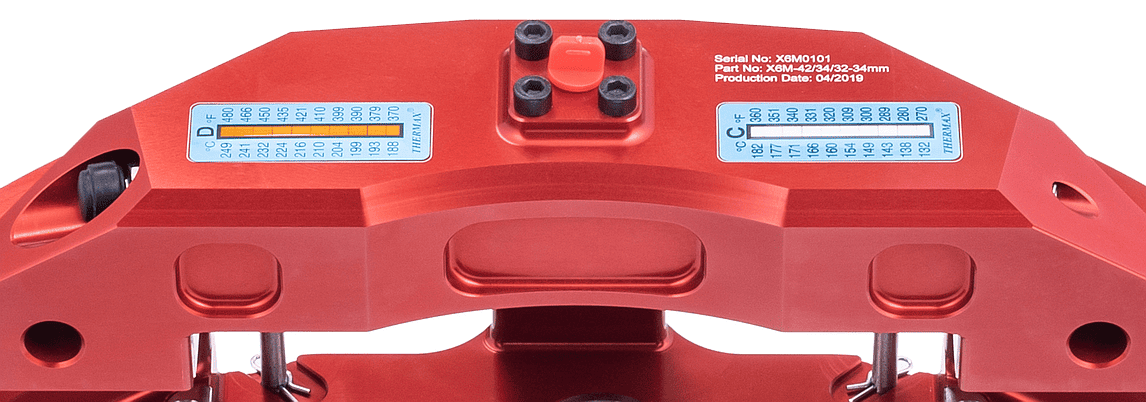

Caliper Maximum Temperature Recording (MTR) System

Caliper Hardware

Caliper Mounting Brackets

Brake Lines

Brake Simulation Software

Brake Pads

Fitment

Lexus GX470 03-09 – Stage 1 (only) 6 Piston Caliper, 13.7″ 1 piece rotor

Lexus GX460 10+ – Stage 1 (only) 6 Piston Caliper, 13.7″ 1 piece rotor

Lexus LX570 05-15 (M12 Mounting Bracket) – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Lexus LX570 16+ (M14 Mounting Bracket) – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Lexus LX600 22+ – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Toyota 4Runner 3rd Gen 4WD 96-02 – Stage 1 (only) 6 Piston Caliper, 13.7″ 1 piece rotor

Toyota 4Runner 4rd Gen 03-09 – Stage 1 (only) 6 Piston Caliper, 13.7″ 1 piece rotor

Toyota 4Runner 5th Gen 4WD 2010+ – Stage 1 (only) 6 Piston Caliper, 13.7″ 1 piece rotor

– with 14mm bracket mount hole for 14WB calipers AND (12mm inserts included for 14WA calipers usually for 2010 to 2015 year models)

Toyota FJ Cruiser 07-14 – Stage 1 (only) 6 Piston Caliper, 13.7″ 1 piece rotor

Toyota Landcruiser 80 16″ Wheels 90-97 – Stage 2 (Only) 6 Piston Caliper, 13″ 2 piece rotor

Toyota Landcruiser 80 17″ Wheels 90-97 – Stage 2 (Only) 6 Piston Caliper, 13.7″ 2 piece rotor

Toyota Landcruiser 200 05-15 – (M12 Mounting Bracket) – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Toyota Landcruiser 200 16+ – (M14 Mounting Bracket) – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Toyota Sequoia 1st Gen 4WD 6 Lug 01-07 – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Toyota Sequoia 2nd Gen 08-15 – (M12 Mounting Bracket) – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Toyota Sequoia 2nd Gen 16-21 – (M14 Mounting Bracket) – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Toyota Tundra 1st Gen 4WD 6 Lug 00-06 – Stage 1 (only) 6 Piston Caliper, 13.7″ 1 piece rotor

Toyota Tundra 2nd Gen 08-15 – (M12 Mounting Bracket) – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Toyota Tundra 2nd Gen 016-21 – (M14 Mounting Bracket) – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Toyota Tundra 3rd Gen 22+ – Stage 1 (only) 6 Piston Caliper, 14.6″ 1 piece rotor

Toyota Tacoma 2nd Gen 4WD 6 Lug 05-15 – Stage 1 (only) 6 Piston Caliper, 13.7″ 1 piece rotor

Toyota Tacoma 3rd Gen 4WD 6 Lug 16-23 – Stage 1 (only) 6 Piston Caliper, 13.7″ 1 piece rotor